Tired of unexpected bearing failures disrupting your production schedule?

Have you ever wondered why some bearings last years while others fail within months in similar applications?

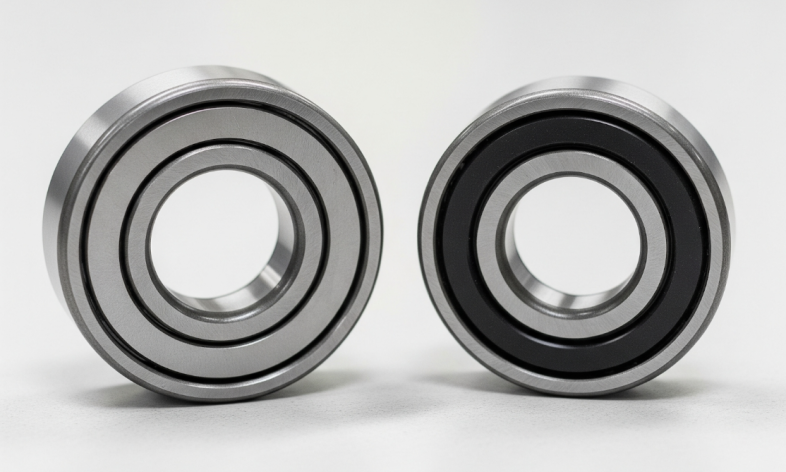

The difference often comes down to one critical decision: choosing between shielded and sealed bearing protection.

If you’re a maintenance manager, engineer, or purchasing agent responsible for keeping equipment running smoothly, this choice directly impacts your success. The wrong bearing protection leads to costly downtime, frustrated operators, and emergency replacement orders that blow your maintenance budget. Meanwhile, selecting the right protection ensures reliable operation, predictable maintenance schedules, and the peace of mind that comes with properly specified equipment.

This comprehensive guide cuts through the technical jargon to provide practical answers for real-world bearing selection challenges. You’ll discover exactly when to choose shielded versus sealed bearings, how to evaluate your specific application requirements, and what questions to ask to avoid costly mistakes.

Whether you’re dealing with wash-down environments, high-speed motors, or contaminated conditions, you’ll have the knowledge to make confident bearing decisions that protect both your equipment and your reputation.

Why Bearing Enclosures Matter: 6 Red Flags That Your Bearing Needs Protection

Open bearings without shields or seals leave internal components completely exposed to environmental contamination, making them suitable only for enclosed machinery with dedicated lubrication systems. While open bearings offer maximum speed capabilities and lowest friction, they’re vulnerable to dust, moisture, and debris that can destroy performance within hours in harsh conditions.

Both shielded and sealed bearings provide essential protection that open bearings cannot match.

Metal shields create a physical barrier against larger contaminants while maintaining the speed advantages of open bearings. Sealed bearings go further, using rubber or contact seals to block fine particles, moisture, and chemicals that would easily penetrate both open and shielded designs. Non-contact seals offer a middle ground, providing better protection than shields while avoiding the friction penalties of contact seals.

Recognizing these warning signs helps determine when open bearings are inadequate and whether your application requires shielded or sealed protection:

- Visible dust accumulation on equipment – Fine particles settling on machinery surfaces indicate airborne contaminants that will infiltrate open bearings and compromise lubrication.

- Presence of liquids or wash-down procedures – Water exposure from cleaning operations requires sealed bearing protection that open and shielded bearings cannot provide.

- Outdoor or semi-outdoor installations – Weather exposure, temperature fluctuations, and environmental debris overwhelm open bearing designs.

- Previous bearing failures due to contamination – Recurring failures from dirt, moisture, or chemical exposure signal that open bearings lack adequate protection.

- High-vibration environments – Excessive vibration accelerates contamination ingress in open bearings, requiring enclosed designs.

- Extended maintenance intervals – Applications where regular lubrication and inspection are impractical demand sealed, maintenance-free operation over open bearing designs.

These evaluation methods provide the technical foundation for informed bearing selection decisions. However, specific application questions often require expert guidance to ensure optimal performance and cost-effectiveness.

Head-to-Head Comparison: Analyzing Shielded vs Sealed Bearings Performance

Understanding the performance trade-offs between shielded and sealed bearings requires examining key operational characteristics that directly impact equipment reliability and maintenance costs. While both designs offer superior contamination resistance compared to open bearings, their different construction methods create distinct advantages and limitations across critical performance metrics.

- Shielded bearings excel in applications prioritizing speed capabilities and low friction operation.

Shielded bearings can be non-contact or contact style, however the non-contact metal shield design maintains the high-speed potential of open bearings while providing protection against larger contaminants. This makes them ideal for electric motors, fans, and precision machinery where rotational efficiency matters. However, the gap between shield and inner ring allows fine particles and moisture to penetrate, requiring more frequent maintenance in harsh environments.

- Sealed bearings sacrifice some speed capability for comprehensive contamination protection.

Sealed bearings can be non-contact or contact style as well, contact seals create friction that reduces maximum RPM ratings by approximately 30-40% compared to shielded equivalents, but they excel in blocking dust, moisture, and chemicals that would destroy open or shielded bearings. The rubber seal construction also limits temperature capabilities, typically operating effectively up to 212°F versus 250°F for metal shields.

| Shielded Bearings | Sealed Bearings | |

|---|---|---|

| Contamination Protection Level | Good against large particles, limited against fine dust and moisture | Excellent against all contaminants including liquids and fine particles |

| Material | Shield = partial protection, low friction, often metal. | Seal = full protection, more friction, often rubber, NBR, PTFE, elastomer but not always. |

| Speed Capabilities | Similar to open bearing performance | Reduced by 30-40% due to seal friction |

| Maintenance Requirements | Regular inspection and relubrication needed | Maintenance-free, pre-lubricated for life |

| Cost Considerations | Lower initial cost, higher long-term maintenance | Higher initial cost, lower total ownership cost |

| Noise Levels | Quieter operation due to no seal contact | Slightly higher noise from seal friction |

| Installation Flexibility | Can service and sometimes relubricate in place | Difficult to relubricate, typically requires full replacement |

| Temperature Range | Typically up to 250°F with standard grease, can get up to 550°F+ in high temp models | Limited to 212°F with standard rubber seals, up to 550°F+ high temp models available |

Need Help Deciding Between Shielded vs Sealed Bearings? Our Experts Can Assist

Selecting the optimal bearing protection for your specific application requires balancing multiple technical factors that impact both performance and total cost of ownership. While this comparison provides general guidelines, real-world applications often present unique challenges that demand expert analysis of operating conditions, maintenance capabilities, and performance requirements.

Central Surplus’s technical specialists bring years of experience helping industrial customers navigate complex bearing selection decisions. Don’t risk costly bearing failures or suboptimal performance due to incorrect bearing selection.

Contact our bearing experts today for a free consultation on your shielded vs sealed bearing requirements – we’ll help you identify the right protection level while ensuring compatibility with your existing equipment and operational procedures. With a wide range of bearings available to ship fast on our eBay store, we’ve got you covered, no matter your requirements.

8 Ways to Know Whether Seals or Shields are Ideal for Your Situation

Determining the optimal bearing protection requires systematic evaluation of your operational environment and performance requirements. Rather than relying on guesswork or generic recommendations, these diagnostic methods provide concrete data to guide your shielded vs sealed bearing decision. Each assessment reveals specific factors that influence bearing selection and long-term performance.

Environmental conditions often provide the clearest indicators for bearing protection needs. High-speed applications with minimal contamination typically favor shielded bearings, while harsh environments with moisture, chemicals, or fine particles demand sealed protection. Understanding your specific operational challenges through targeted evaluation ensures optimal bearing performance and cost-effectiveness.

These diagnostic steps help identify whether seals or shields best match your application requirements:

- Conduct the paper test – Place white paper near operating equipment for 24 hours to visualize airborne contamination levels that could penetrate bearing protection.

- Check your maintenance schedule – Applications with infrequent maintenance access require sealed bearings, while easily serviceable equipment can utilize shielded options.

- Review past bearing failures – Analyze failure modes to determine if contamination, overheating, or lubrication issues drove previous replacements.

- Measure your environment – Document temperature ranges, humidity levels, and chemical exposure to match bearing materials and seal compatibility.

- Audit your cleaning procedures – Wash-down operations and high-pressure cleaning require sealed bearing protection that shields cannot provide.

- Calculate downtime costs – High-cost production interruptions justify sealed bearings’ higher initial price through reduced failure rates.

- Assess speed requirements – Applications exceeding 70% of sealed bearing speed ratings benefit from shielded alternatives’ unlimited speed capabilities.

- Evaluate lubrication access – Equipment with grease fittings can utilize shielded bearings, while inaccessible locations need maintenance-free sealed designs.

7 Helpful Questions to Clear Up the Shielded vs Sealed Bearings Debate

These frequently asked questions address the most common concerns maintenance professionals and engineers face when selecting between shielded and sealed bearing protection. Understanding these key distinctions helps eliminate confusion and ensures optimal bearing selection for your specific operational requirements.

- Can I use sealed bearings in high-speed applications without performance penalties? – Sealed bearings reduce maximum speed capabilities by 30-40% due to contact seal friction. For applications requiring speeds above 70% of the sealed bearing rating, shielded bearings maintain full speed potential while providing adequate protection in moderately clean environments.

- Will shielded bearings protect against moisture and wash-down procedures? – Metal shields cannot prevent moisture infiltration due to the gap between shield and inner ring. Water exposure from cleaning operations or humid environments requires sealed bearing protection with rubber seals that create a moisture barrier.

- Are sealed bearings worth the higher initial cost compared to shielded alternatives? – Sealed bearings typically cost 20-30% more initially but eliminate maintenance requirements and extend service life in contaminated environments. Calculate total ownership costs including maintenance labor and replacement frequency to determine long-term value.

- Can I relubricate shielded bearings but not sealed bearings during operation? – Shielded bearings allow access for relubrication through the shield gap, making them serviceable during equipment operation. Sealed bearings come pre-lubricated for life and cannot be relubricated, requiring complete replacement when lubrication degrades.

- Do sealed bearings generate more heat and noise than shielded bearings? – Contact seals create friction that generates slightly more heat and operational noise compared to non-contact shields. However, modern seal designs minimize these effects, and the performance difference is negligible in most industrial applications.

- Are all shielded bearings metal, and are all sealed bearings rubber? –

“Metal” Shielded Bearings

- Most shields are metal (typically steel or stainless) because their purpose is to deflect debris while allowing low-friction rotation.

- However, some specialty shielded bearings use non-metallic shields (like reinforced plastic or composite) in applications where corrosion resistance, weight reduction, or electrical insulation is important.

- Shields don’t typically make full contact with the inner race — they’re more for blocking larger contaminants while keeping grease in.

“Rubber” Sealed Bearings

- Many seals are rubber-based (often nitrile rubber/NBR, fluorocarbon/Viton, or similar elastomers) bonded to a steel core for stiffness.

- But not all are rubber — some are labyrinth seals or PTFE seals for high-temp or chemical applications, and some are fully metal contact seals.

- Seals usually make light contact with the inner race to better retain lubricant and block contaminants.

Enhance Your Operations by Making the Smart Choice on Shielded vs Sealed Bearings

The choice between shielded and sealed bearings directly impacts equipment reliability, maintenance costs, and operational efficiency across your industrial applications.

Understanding the performance characteristics, environmental requirements, and cost implications enables informed decisions that optimize both immediate performance and long-term value. Whether your application demands the speed capabilities of shielded bearings or the comprehensive protection of sealed designs, selecting the appropriate bearing protection prevents costly failures and unexpected downtime.

Central Surplus stocks comprehensive inventories of both shielded and sealed bearings from leading manufacturers including SKF, Timken, NSK, and FAG. Our technical experts provide personalized guidance to ensure optimal bearing selection for your specific requirements.

Don’t compromise equipment reliability with incorrect bearing protection – contact Central Surplus today or browse our eBay storefront for competitive pricing on industrial bearings. Our extensive selection, technical expertise, and fast shipping ensure you get the right bearing protection when you need it most.